Electrostatic Precipitation (ESP) Fundamentals

ELECTROSTATIC PRECIPITATOR PROCESSES & PARTICULATES

Fundamentals of Precipitators

How Does ESP Work?

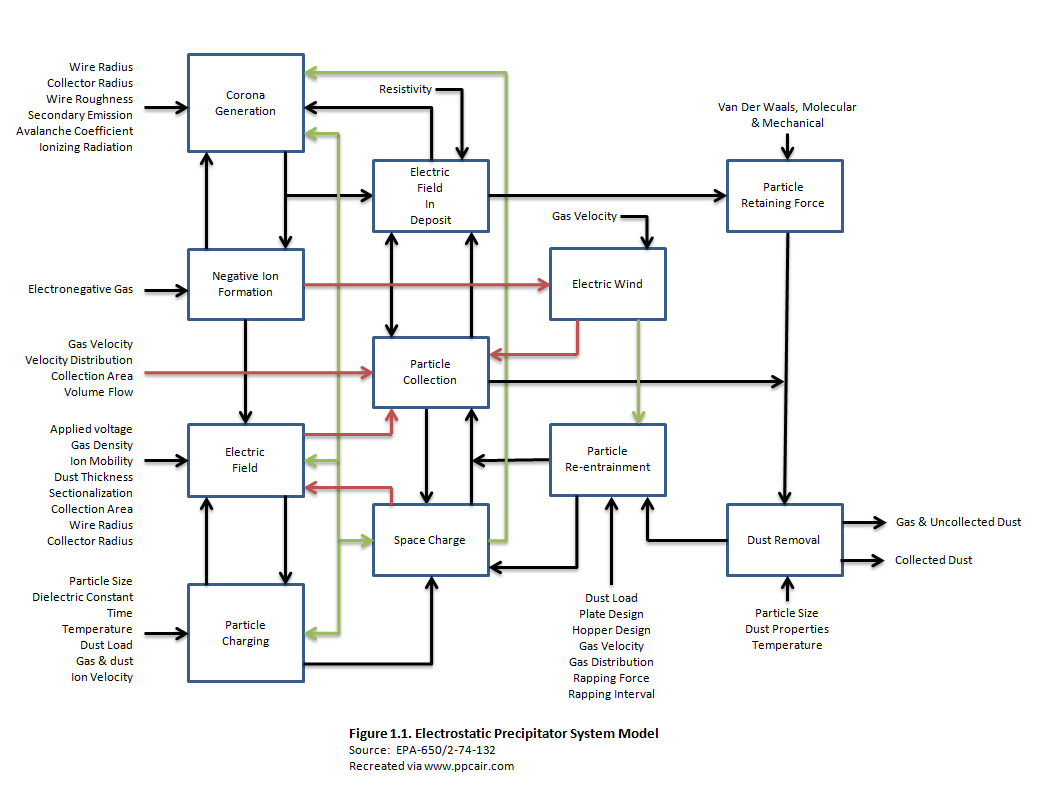

In the simplest terms, a precipitator is a device that utilizes electrostatic forces for the collection of particulate. The particulate laden gases enter one area of the vessel and exit another area clean. Inside, high voltage electrodes impart a charge to the particles. Most modern precipitators utilize negative voltage electrodes though positive voltage electrodes do exist. These charged particles are then attracted to a collecting surface (grounded, neutral or oppositely charged). The particles build up on the collection surfaces over time and are then periodically removed, typically at set intervals.

What are the Different Types of ESP’s?

The vast majority of Industrial Electrostatic Precipitators are of the dry type, though wet precipitators are gaining popularity. Dry Electrostatic Precipitators are often referred to as Dry ESP's or DESP's while the Wet Electrostatic Precipitators are referred to as Wet ESP's or WESP's. Regarding particulate removal, the surfaces in a Dry ESP are rapped or vibrated, and the tubes in a Wet ESP are flushed , causing the particles to separate from the collection surface. In a Dry ESP the particles are usually evacuated from the hopper by rotary screws or drag chain conveyors . In a Wet ESP the hoppers are designed to gravity drain or pump the flush water for designated treatment or disposal.

Wide Range of Collectible Particles

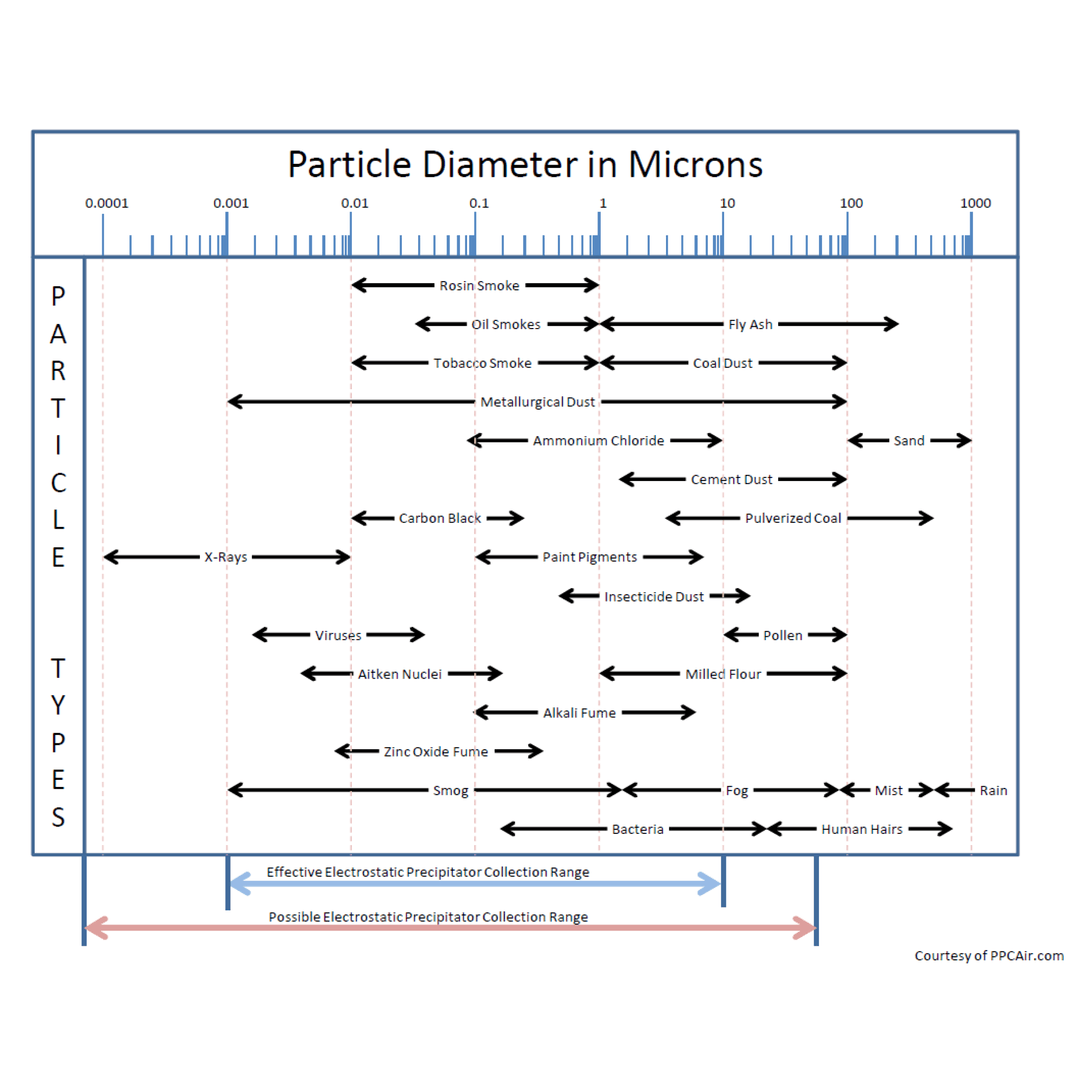

Precipitators can be used to collect many different kinds of particles with a wide range of physical properties. Some of the compounds that can be collected include:

- Aluminum

- Ammonium Sulfates

- Arsenic

- Asphalt

- Bagasse Ash

- Bentonite

- Catalyst

- Cement

- Coal Ash

- Coke

- Copper

- Diesel Smoke

- Fluorspar

- Fly Ash

- Glass

- Gold

- Grease

- Gypsum

- Hydrochloric Acid

- Hydrofluoric Acid

- Incinerator Ash

- Iron Oxide

- Lead

- Oil

- Pigments

- Plastic

- Salt Cake

- Smoke

- Sulfuric Acid Mist

- Tar

- Wood Ash

- Wood Acids

- Wood Tar

Processes Employing Precipitators

Precipitators have been employed on many separate processes and pieces of process equipment such as:

- Biofuel Production

- Biomass to Energy

- Ethanol Production

- Food Processing

- Glass Making

- Oil Refineries

- Paint Processing

- Pellet Mills

- Plastic Processing

- Pulp and Paper

- Semiconductors

- Sugar Mills

- Waste Disposal

- Waste to Energy

- Wood Products

Determining Size

The basic size of a precipitator can be determined through the Deutsch-Anderson Equation.

- A = -( Q / w ) x [ ln ( 1 - Eff ) ]

- Where:

- A = collection area required in square feet.

- w = Drift or Migration velocity of the particles to be collected.

- Q = Gas Flow Rate in cubic feet per second.

- Eff = Fractional collection efficiency desired.

- Drift velocity or migration velocity can be specifically defined as:

- w = dp x Eo x Ep / (4πµ)

- Where:

- dp =diameter of particle, microns

- Eo =strength of field in which particles are charged, V/m (V/ft)

- Ep = strength of field in which particles are collected, V/m (V/ft)

- µ = Gas viscosity, Pa *s (cp)

- π = 3.1415

Each type of particulate or process gas stream has a different migration or drift velocity associated with it. Once the process or particulate source is known a range of drift velocities can be selected. It is important to note that the drift velocities shown below are highly dependent upon not only the upstream process but the configuration and design of the precipitator as well. For example two identical processes each with their own precipitator made by a different manufacturer will often have different apparent drift velocities. This is because each manufacturer has a different physical design in terms of gas flow, electrode design and power supplies.

The calculator below can be used to determine the rough size of a precipitator.

PPC has completed over 500 successful air pollution & particulate control projects, and with over 40 years of experience PPC has been a stable force in the field of electrostatic precipitation.

Have questions about Electrostatic Precipitation (ESP) - Dry ESP?

Ask a PPC Industries Expert