Dry Acid Gas Scrubbing - Overview

Dry Acid Gas Scrubbing Design and Operation

DRY ACID GAS SCRUBBING: SO2, SO3, HF, HCI CONTROL

Up to 85% Control of SO2

Up to 95% control of SO3, HCL & HF

- Easily installs ahead of existing particulate controls (e.g. dry electrostatic precipitator or baghouse)

- Minimal footprint

- Lower installed capital cost than limestone slurry scrubber or spray dryer.

- Possible to use existing duct work with minimal modifications

- No water discharge requirements

- Used reagent and reaction products are handled with existing ash handling equipment and disposed of with the ash.

- Pre Wired

- PLC Controlled

General

PPC’s dry powder injection (DPI) system, is designed to control acid gas emissions from boilers and other combustion sources by injecting sodium reagents such as sodium bicarbonate (NaHCO3) or trona (sodium sesquicarbonate – Na3(HCO3)(CO3)•2H2O) directly into the flue gas, to neutralize acid gases.

Sodium reagents are used instead of calcium reagents (i.e. limestone – CaCO3) because they are more reactive. This results in less reagent and less time required to neutralize acid the gases. An added benefit is improved precipitator performance.

Principle of Operation

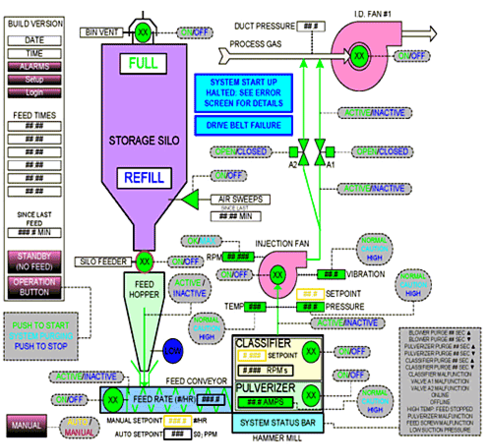

The DPI system relies on gas/solid reaction and the efficiency and effectiveness of the reaction depends on the surface area of the solid injected into the flue gas. To maximize the reagent surface area, PPC designs a self contained injection system which includes reagent milling, feed rate regulation, a classifying mill and an injection blower to deliver the milled reagent into the exhaust gas.

The milled reagent is delivered to the exhaust gas duct work where it mixes with the exhaust gas and reacts with the acid gases, forming solid sodium salts. These salts are then collected in existing particulate control devices, and removed using existing ash handling systems.

System Design

PPC designs the DPI system to deliver the necessary amount of milled reagent to achieve the desired removal efficiency. The system is self contained and skid mounted and includes the reagent feed control, classifying milling system and the injection blower.

The system includes a raw material storage silo, power distribution panel, motor starters and variable frequency drives as well as a pre-programmed PLC control system. The DPI system is shipped with all motors and instrumentation mounted.