Electrostatic Precipitation (ESP) - Dry ESP

Dry ESP Service & Technical Information

How It Works

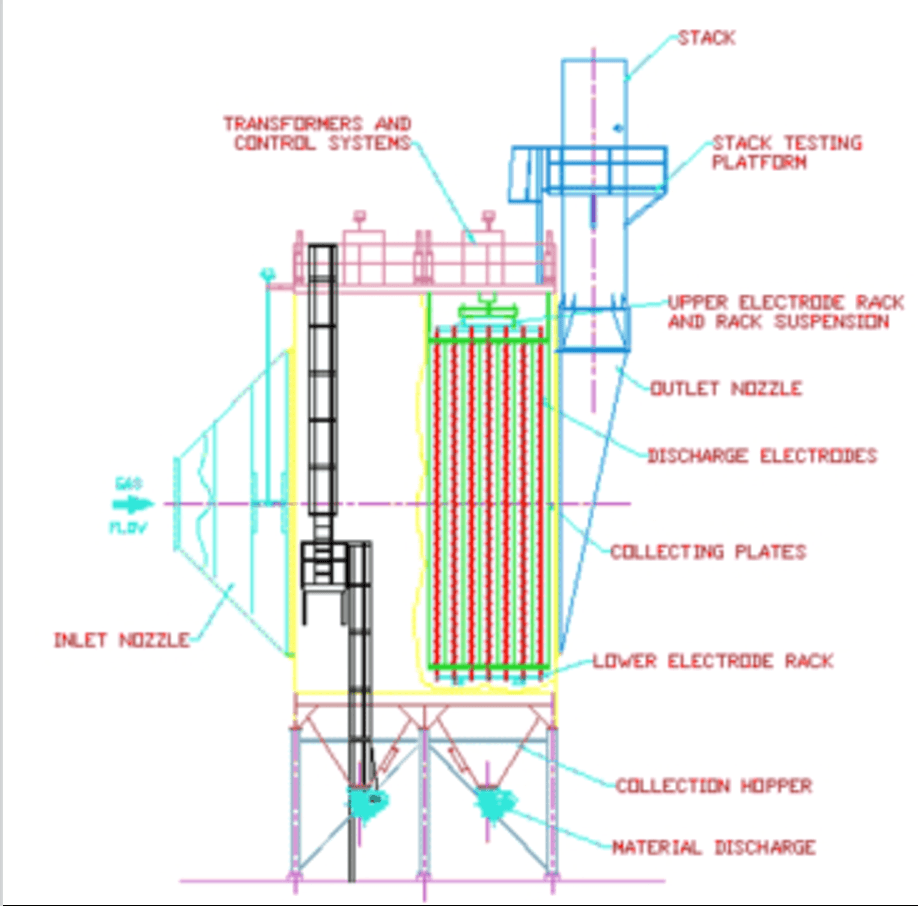

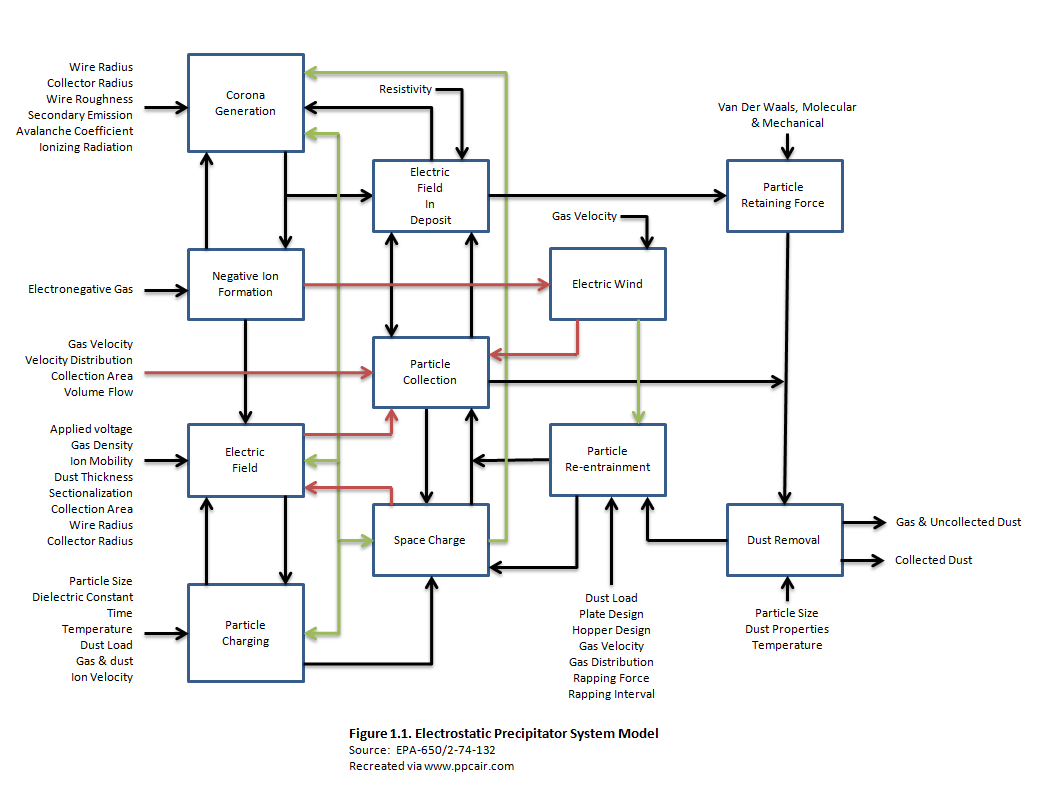

Particulate control begins when the dust laden gases enter into the unit. Inside, high voltage electrodes impart a charge to the particles entrained in the gas. These charged particles are then attracted the grounded collecting surfaces. The gas then leaves the unit up to 99.9% cleaner than when it entered.

The negatively charged rigid type discharge electrodes are accurately centered between the collecting surfaces and supported from high voltage insulators located in insulator compartments on the ESP.

The particulate control process inside the box does not end with the initial collection. The particles from the continuous dirty gas flow build up on the collecting plates and need to be removed. At periodic intervals, the collecting plates are rapped or vibrated causing the particles to fall into the hoppers. The collected particles are then removed from the hoppers by a screw conveyor or rotary airlock or a combination thereof.

Precipitator Service

One of the most important considerations in design and operation of the dry electrostatic precipitator (ESP) is the removal of the collected material from the collecting surfaces without re-entraining it in the gas stream, this ensures compliance with Federal Standards (MACT), State SIPS (State Implementation Plans) and local regulations. On PPC dry electrostatic precipitators (ESP), material removal from the plates is accomplished by electromagnetic rappers or sonic horns installed on the roof section. Rappers deliver hammer blows of preset intensity at preset intervals to the plate headers creating a vertical shock wave while sonic horns deliver a system wide sonic wave that simultaneously vibrates all surfaces at once. A shock wave, however it is created, causes the collected material to shear off and fall into the hopper. The wave intensity and interval is dictated by the characteristics of the deposited material. These adjustments are made to the particulate removal system to suit the requirements of each installation and are a part of the dry electrostatic precipitator (ESP) start up service provided by PPC.

As opposed to conventional hoppers, the PPC dry electrostatic precipitator (ESP) hoppers have integral, support members which simplifies support steel fabrication and structural steel erection. Additionally this allows shop installation of insulation and heaters at substantial savings. PPC dry electrostatic precipitator hopper openings are a minimum of 18" wide to allow free flow of ash and eliminate bridging. Hopper depth is kept to a minimum to reduce cooling of ash and subsequent caking.

Maximum effectiveness of the dry electrostatic precipitator particulate control system occurs when the voltage supply output reaches the sparking threshold. Variation in gas volume, dust loading and other factors, however affect the sparking threshold level. Employing an advanced electrical control system, an automatic control circuit regulates each high voltage power supply output for maximum dry electrostatic precipitator (ESP) efficiency regardless of process variation. Sparking causes the power supply to "notch down" slightly with the automatic controls bringing it right back up to sparking potential. Modern digital electronic controls automate this process and assure the ESP particulate control device operates at peak performance levels at all times, ensuring compliance with MACT guidelines as set forth by the EPA.

PPC has completed over 500 successful air pollution & particulate control projects, and with over 40 years of experience PPC has been a stable force in the field of electrostatic precipitation.

Have questions about Electrostatic Precipitation (ESP) - Dry ESP?

Ask a PPC Industries ExpertInstallations

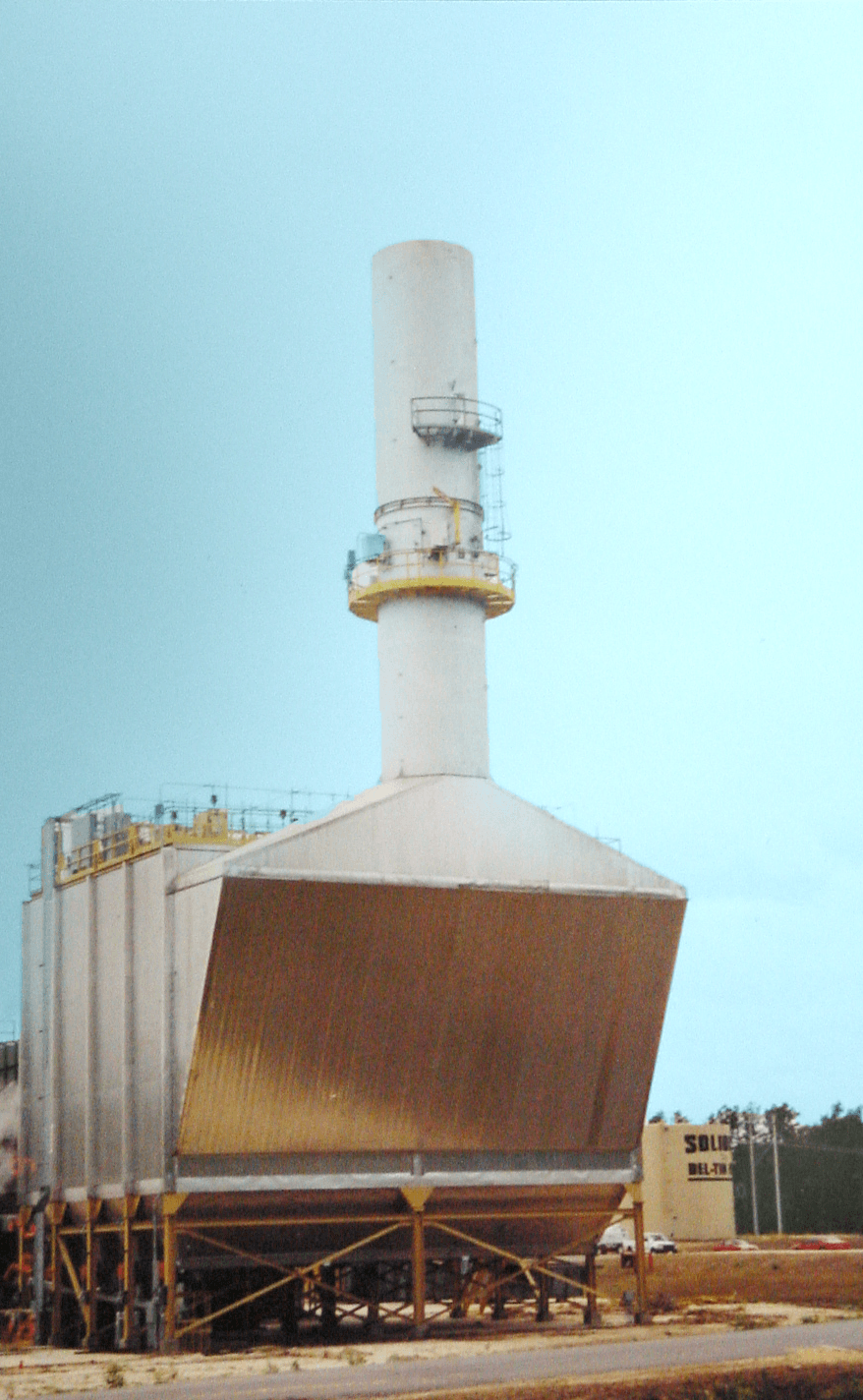

540,000 ACFM - Waste Wood Combuster

- Application: Waste Wood Combustion Emissions Control

- Industry: Medium Density Fiberboard Manufacturin

- Location: Arkansas

- Air Flow: 540,000 ACFM

- Objective: MACT Compliance

- Notes: Replaced Baghouse

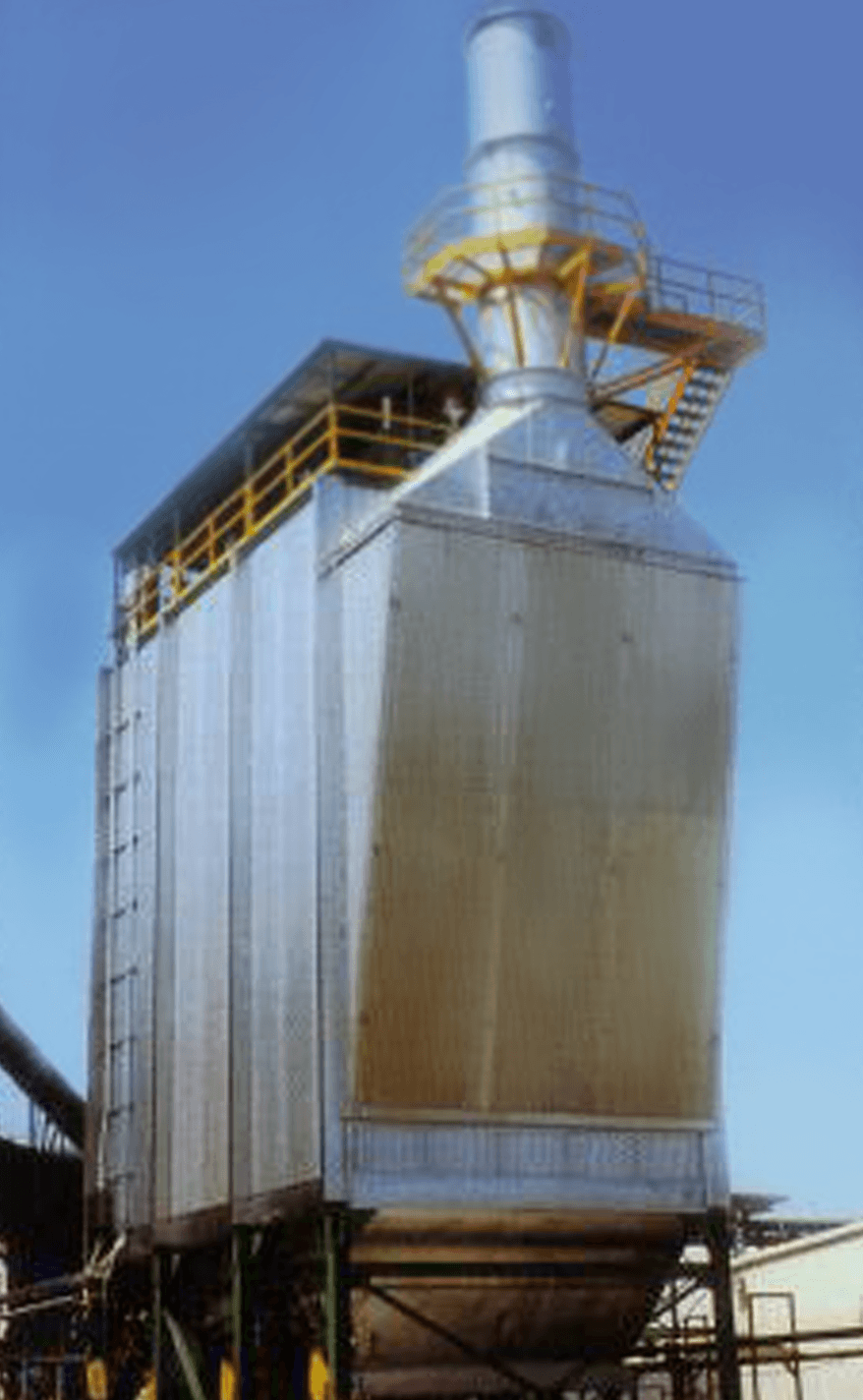

132,000 ACFM - Wood Fired Boiler

- Application: Wood Fired Boiler Emissions Control

- Industry: Plywood Manufacturing Plant

- Location: Alabama

- Air Flow: 132,000 ACFM

- Pollutants: Ash Particulate

- Objective: EPA Compliance

- Notes: Replaced Wet Scrubber

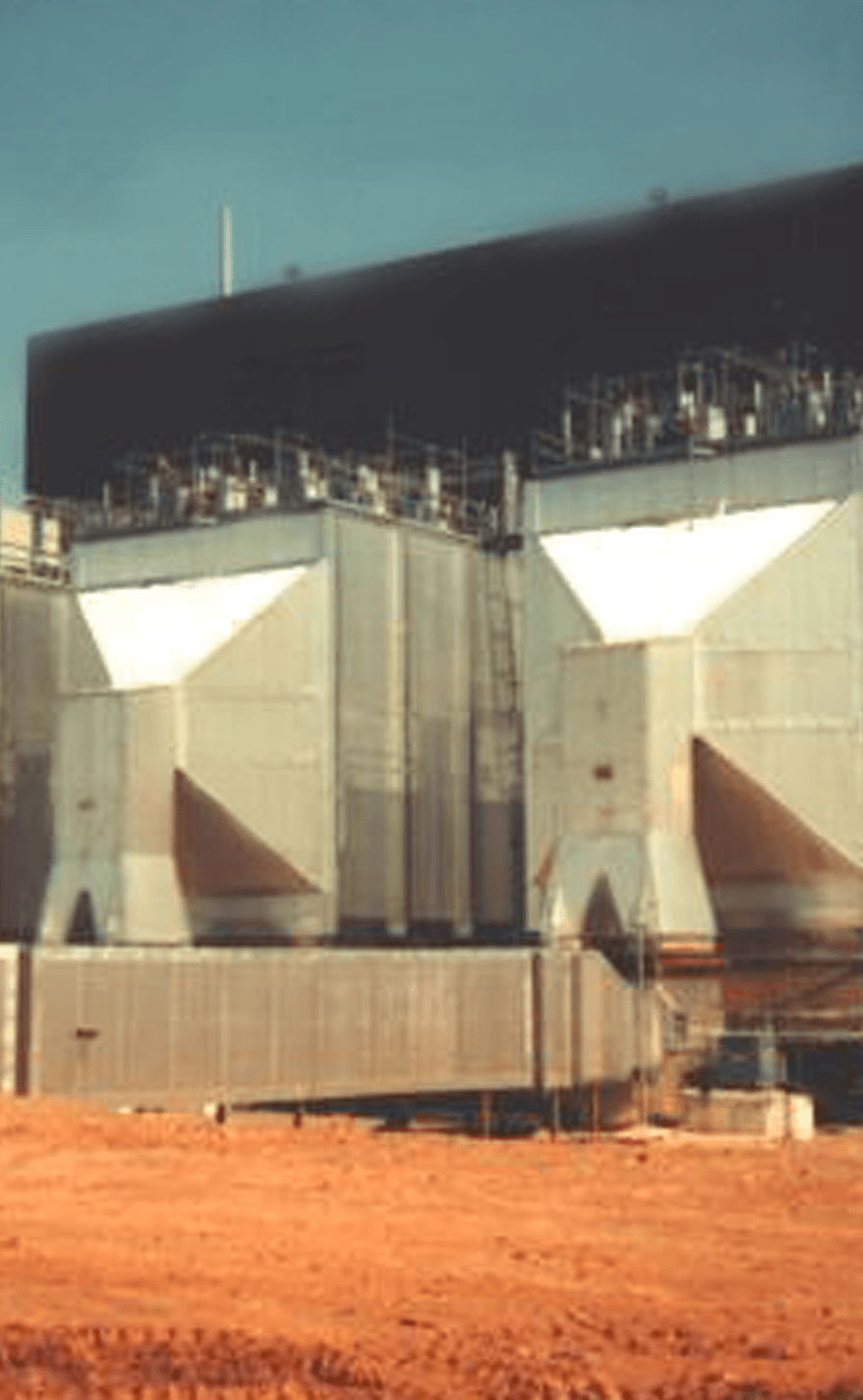

900,000 ACFM - Cogeneration

- Application: 80 Megawatt Cogeneration Facility Boiler Flue Gas Emissions Control

- Industry: Cogeneration

- Location: Virginia

- Air Flow: 900,000 ACFM

- Pollutants: Wood & Coal Ash

- Objective: Particulate Compliance

- Notes: Three 300,000 ACFM ESP’s operating in parallel on three 250,000 pph Boilers

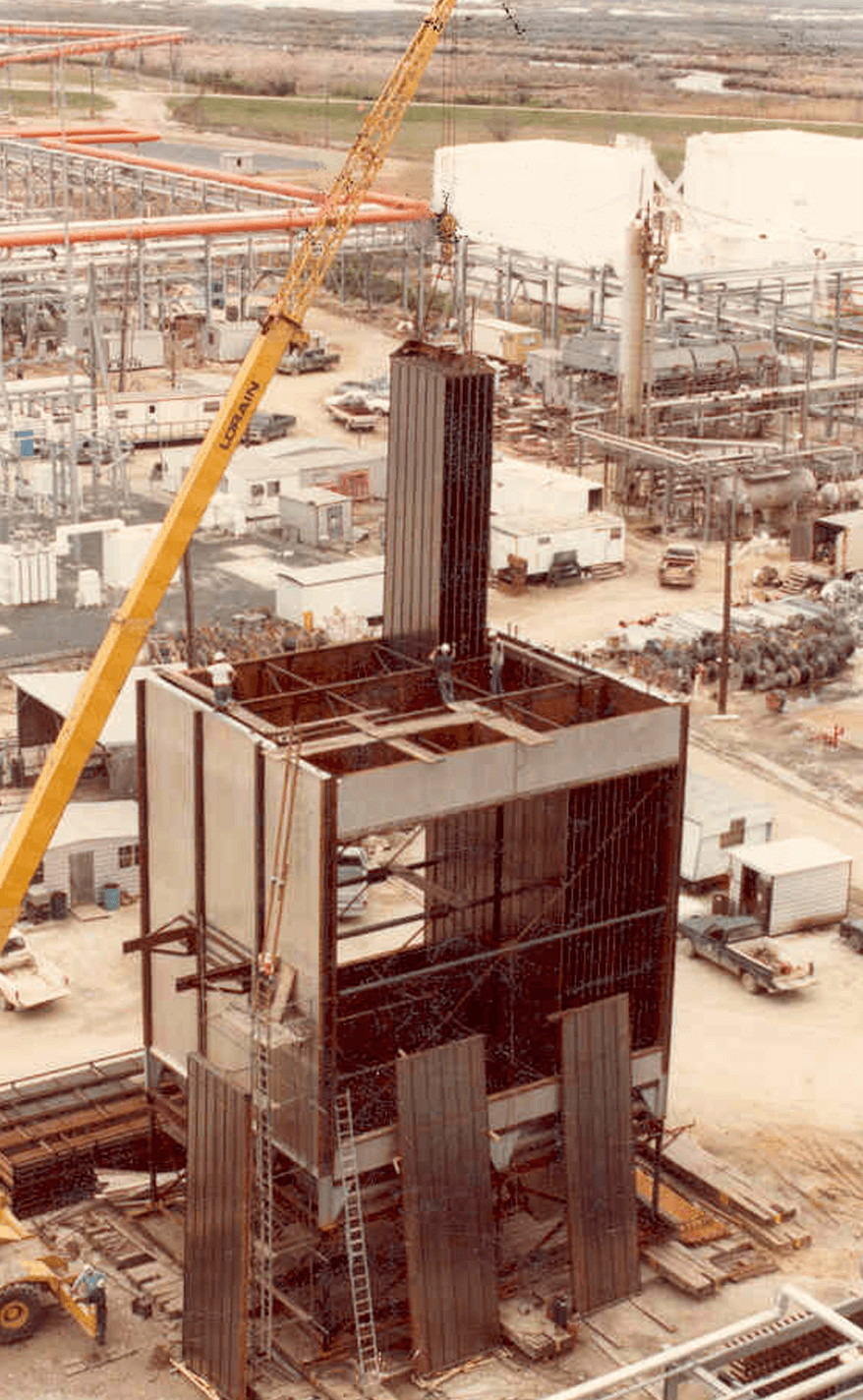

200,000 ACFM - Fluid Catalytic Cracker Unit

- Application: Treatment of Flue Gas Emissions from a FCCU

- Industry: Refining

- Location: Texas

- Air Flow: 200,000 ACFM

- Pollutants: Catalyst Fines

- Objective: Particulate Compliance

- Notes: Installed on top of a 13 story FCCU

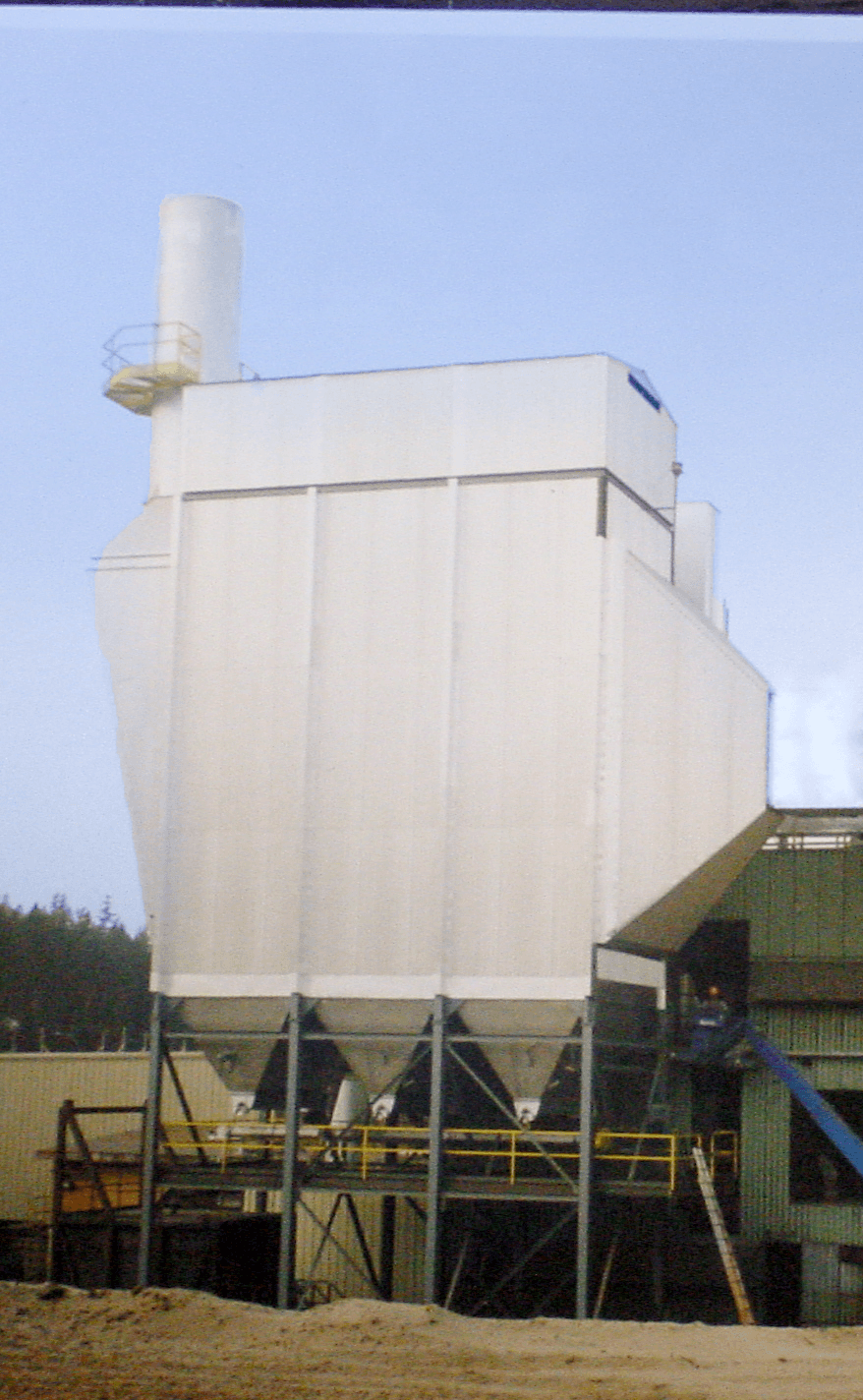

120,000 ACFM - Wood Fired Boiler

- Application: Wood Fired Boiler Emissions Control

- Industry: Plywood and Lumber

- Location: British Columbia, Canada

- Air Flow: 120,000 ACFM

- Pollutants: Ash Particulate

- Objective: EPA Compliance

- Notes: Installed on Elevated Structural Steel

15,000 ACFM - Medical Waste Incineration

- Application: Incineration Emission Control

- Industry: Medical Waste Incineration

- Location: Florida

- Air Flow: 15,000 ACFM

- Pollutants: HCL, Sulfur Dioxide, Incineration Particulates

- Objective: EPA Compliance

- Notes: This system included a Dry Powder Sodium Bicarbonate SO2/HCL Scrubber followed by a 3 field ESP

85,000 ACFM - Glass Manufacturing

- Application: Glass Plant Furnace Flue Gas Emissions Control

- Industry: Glass Bottle Manufacturing Facility

- Location: California

- Air Flow: 85,000 ACFM

- Pollutants: Sub Micron Chloride Particulates

- Objective: Particulate Compliance

- Notes: Single Unit control device for three separate furnaces